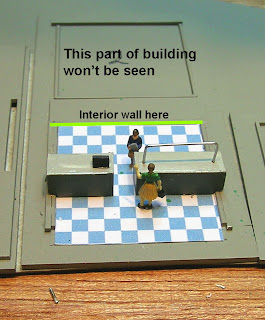

The first step was to create a believable floor so I used Microsoft Visio to make a simple pattern and printed that on white paper and glued to the base. The tiles scale out to about 16 inches.

Next I needed just enough detail parts to make it look right. I made a pair of counters from scraps of styrene with one having a cash register and the other having a pole / rail to hang finished cleaning. This was made of .010 brass rod.

I only had to detail the front half of the building as the back half, the actual dry cleaning plant will be hidden by an interior

wall.

I then went back to the computer and created what I thought would be the appropriate wall features again using Microsoft Visio. A photo of a dry cleaning trolley system was found then reduced and added to the wall to simulate the room beyond the wall. As I don't yet know how to incorporate Japanese characters into a sign I could print, the price list is just gibberish that will be too small for anyone to actually see. This was then glued to the inside walls of the front of the building.

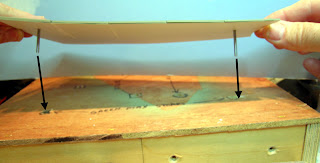

Interior details won't be seen if they are not lighted. I added 2 bright LED light boards from Atlas engines with the LED bent down from the ceiling.

Here is the finished dry cleaning store with the LED's on. To make working with the interior easier I did not install the front window & door part until just prior to mounting the building on the base and had selected one that is mostly clear.

Here is the finished dry cleaning store with the LED's on. To make working with the interior easier I did not install the front window & door part until just prior to mounting the building on the base and had selected one that is mostly clear.The next store to receive this treatment will be a book store in the same block.